The Virtual Fabrication Access Bridge: When five universities become one research and development powerhouse

Virginia introduces the nation’s first statewide semiconductor fabrication access platform — uniting tools, people, and possibilities.

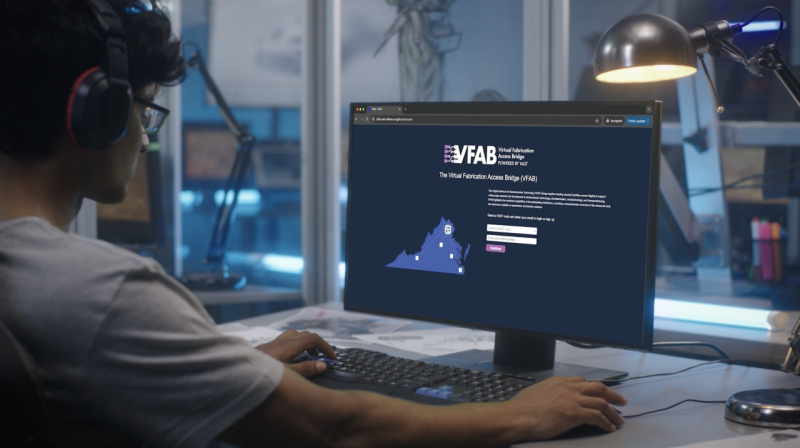

In a major step toward transforming the microelectronics innovation landscape, Virginia has launched the Virtual Fabrication Access Bridge (VFAB) powered by the Virginia Alliance for Semiconductor Technology (VAST). The first-of-its-kind statewide online platform connects more than 170 advanced semiconductor tools across five universities under a single, unified access system.

VAST, which welcomes opportunities for collaborating and expanding beyond Virgina, created the platform to address a critical national challenge: the lack of broad, equitable access to fabrication infrastructure for education, research, and industry.

"We are proud to celebrate a major milestone with the launch of the Virtual Fabrication Access Bridge — a groundbreaking statewide platform that exemplifies VAST’s mission to build a collaborative, innovation-driven semiconductor ecosystem in Virginia,” said Masoud Agah, executive director of the alliance. “It stands as a powerful example of how VAST turns shared vision into real, scalable infrastructure."

How it works

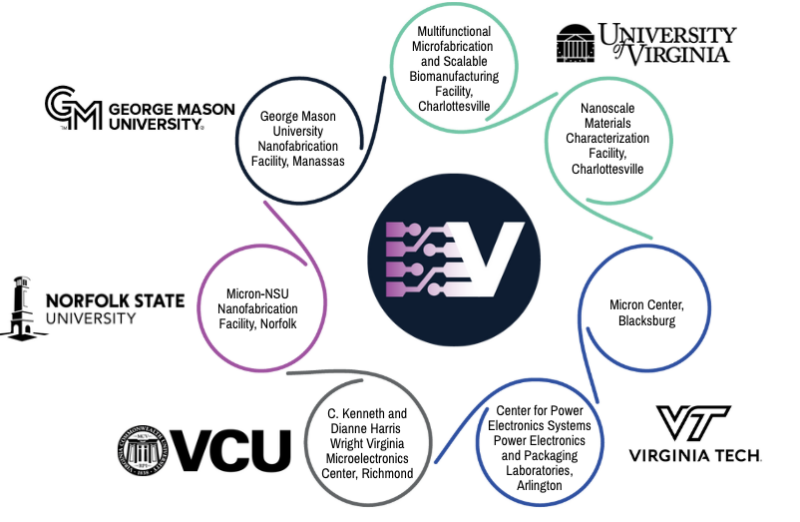

VFAB operates on the facility online manager platform and connects fabrication and characterization tools across:

- University of Virginia

- Virginia Tech

- Virginia Commonwealth University

- Norfolk State University

- George Mason University

Each university’s cleanroom and instrumentation facilities are now searchable and reservable through VFAB’s centralized, cloud-based portal.What’s really exciting about VAST is the partnership,” said Lori McMahon, vice president for research at the University of Virginia. “It takes all of us to work together to achieve the goals and to make the magic happen. The mission of creating new knowledge, creating new materials, and manufacturing those materials is side by side with education and offering opportunities for those looking to be part of something big.

Breaking down barriers in microelectronics access

Until now, universities and startups often faced steep logistical and financial hurdles in accessing high-end semiconductor fabrication equipment. Researchers had to rely on informal connections or redundant procurement.

VFAB removes those barriers with:

- Single sign-on access to all partner university tools

- Home facility designation with visibility across the network

- Integrated reservation, billing, training requests, and usage records

“Before VFAB, if we needed access to a tool not available in our lab, we had to cold-email professors and hope for a collaboration,” recalls Xiaoting Jia, professor in the Bradley Department of Electrical and Computer Engineering at Virginia Tech. “That’s no longer necessary.”

This design supports not just internal university users, but also external academic researchers, startups, small businesses, and large commercial partners.

A strategic asset for national competitiveness

VFAB comes at a pivotal time for American microelectronics. With the CHIPS Act driving historic investment in domestic semiconductor capacity, and the White House’s National Strategy on Microelectronics Research (2022) calling for “expanded access to advanced infrastructure,” VFAB responds to a clear federal mandate.

Federal agencies — including National Science Foundation (NSF), National Institute of Standards and Technology (NIST), and the CHIPS office — have repeatedly identified a lack of physical fabrication access (labs, cleanrooms, multi-project wafer runs) as a core national bottleneck. VFAB directly responds to these calls by offering an open-access, federated model that is both scalable and collaborative .

“The entire VAST initiative is a testament to cross-institutional success,” said Dan Sui, senior vice president and chief research and innovation officer at Virginia Tech. “The fact that six major universities and our community college partners have come together to share facilities and align our curricula is a powerful example in itself.”

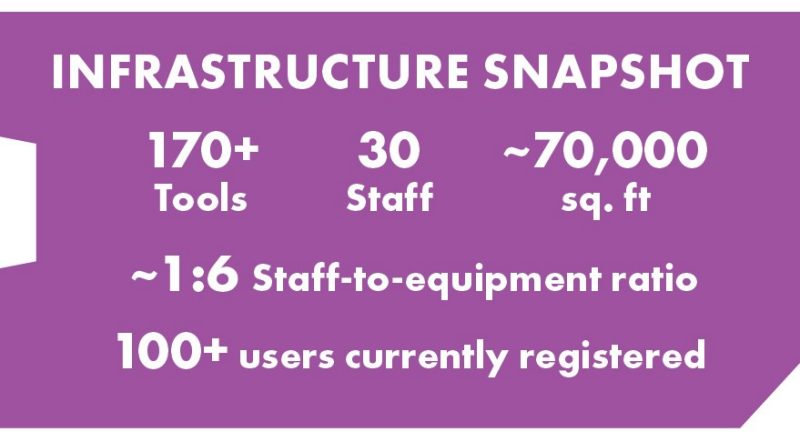

The platform already supports over 100 active users, a 1:6 staff-to-equipment ratio, and more than 65,000 square feet of lab space — positioning it as a scalable node in the national innovation ecosystem.

Specialized tools driving real-world innovation

For industry or research teams exploring whether VFAB fits their needs, tool capability is key.

At the Univeristy of Virginia, for instance, VFAB provides access to instruments like:

- Raith 150 E-Beam Lithography System: Used to “write” structures smaller than viruses, with single-digit nanometer precision, critical for photonic devices and quantum research

- Themis 60–300kV Transmission Electron Microscope: Captures atomic-scale images of materials — essential for battery research, chip materials, and failure analysis

- Quanta 650 SEM: A powerful imaging tool capable of inspecting microchips and materials at magnifications up to 1,000,000x.

“Getting each tool onto this system has been a tremendous effort,” notes Swarnanjali, VAST process engineer at the University of Virginia. “At our university alone, we have more than 75 tools integrated — and each one opens doors for researchers who previously couldn’t access them.”

Serving the full innovation spectrum — from lab to launch

VFAB is built with diverse users in mind:

- 600+ students (undergrad, MS, PhD) use these tools annually

- 200+ faculty research groups across the state benefit from shared access

- Startups and small businesses can prototype without millions in capital costs

- Established commercial partners gain a new channel for affordable R&D

One example: a startup can reserve a $3.5M electron beam lithography tool for an hourly rate — avoiding prohibitive ownership costs while gaining access to world-class fabrication.

“As a former PhD student and founder, I can say this facility made my startup possible,” shares Matthew Hull, title, of Virginia Tech.

Built to scale, backed by the state.

With support from the Virginia General Assembly (H.R. 400) and VAST, VFAB is more than an operational tool — it’s a model for regional research and development coordination.

Key partnerships include:

- VAST Operations Committee for governance

- 5 full-time process engineers embedded across sites

- 170+ tools spanning fabrication, packaging, and metrology

- Secure cloud-based access and billing infrastructure

Future priorities include:

- Expanding the Start-up and Entrepreneurship Ecosystem Development (SEED) access program for startups

- Onboarding new universities and community colleges

- Offering micro-credentials and hybrid training

- Investing in equipment upgrades and staffing for national demand

Download the VFAB one-pager to learn more

“This progress would not be possible without the visionary leadership at our partner universities, whose continued support fuels VAST’s momentum,” Agah said. “We are especially grateful to GO Virginia for their financial backing, which has enabled VAST to grow from concept to execution. I also want to recognize the strategic guidance of the VAST Operations Committee, the dedication of our process engineers, and the tireless leadership of Dr. Prabesh Dulal, who was instrumental at every step of VFAB’s development and launch.”

“This is about more than tool access — it’s about building a sustainable, statewide innovation infrastructure that can grow with the needs of academia, industry, and the nation,” said Prabesh Dulal, associate director of operations for VAST.

The road ahead

“We’re rolling — and it’s incredibly exciting to be part of something this impactful,” said Art Lichtenberger, research professor in the Electrical and Computer Engineering department and University of Virginia’s lead on VFAB implementation.

Whether you're a faculty innovator, a startup prototyping your next chip, or a federal agency looking to invest in scalable workforce training, VFAB opens the door.

It’s not just a platform. It’s a bridge — one that connects tools, talent, and transformation.

What university leadership says:

Norfolk State University is pleased to emphasize our strong support for VFAB, and for the VAST partnership. Since it's inception, our university has been an enthusiastic member of this coalition because this experiment represents a smart path forward. This partnership demonstrates a concrete strategy to grow innovation opportunities for entrepreneurs, while also exposing Virginia's students to state-of-the-art technologies. This effort is great economically, it's great educationally, and it positions the Commonwealth for great possibilities technologically in the years to come.

- Dr. Aurelia T. Williams, Interim Provost and Vice President for Academic Affairs at Norfolk State University

____________________________________________________

VFAB opens the door for local and regional partners across Virginia to access cutting-edge semiconductor tools and expertise through a powerful statewide network. With Mason’s SciTech Innovation District as one of several innovation hubs, this collaboration reflects our shared commitment to inclusive innovation — creating opportunities for students, entrepreneurs, and industry to thrive together in the Commonwealth’s growing tech ecosystem.

- Andre Marshall, Vice President for Research, Innovation and Economic Impact at George Mason University

____________________________________________________

The entire VAST initiative is a testament to cross-institutional success. The fact that six major universities and our community college partners have come together to share facilities and align our curricula is a powerful example in itself.

Dan Sui, Senior VP for Research & Innovation at Virginia Tech

____________________________________________________

What's really exciting about VAST is the partnership. It takes all of us to work together to achieve the goals and to make the magic happen. The mission of creating new knowledge, creating new materials, and manufacturing those materials is side by side with education and offering opportunities for those looking to be part of something big.

Lori McMahon, Vice President for Research at University of Virginia

____________________________________________________

Being a member of VAST gives us huge leverage because Virginia Tech and the state of Virginia now put lots of focus on semiconductor research, and semiconductor research itself is not just Virginia Tech's priority—it's our national priority in terms of building technology competence. This gives us a great opportunity to build an ecosystem where Virginia Tech can contribute our strength and further expand our strength by becoming a national leader.

Rose Hu, Department Head, Electrical & Computer Engineering at Virginia Tech

____________________________________________________

The Virginia Alliance for Semiconductor Technology is actually really important to Virginia Tech. It really is one of those examples where sometimes the problems you're working on are big enough that you can't go it alone. This is a space where we all need to participate—all of the Virginia institutions need to participate. VAST is a great example of being able to bring to bear not just what's best about Virginia Tech or any other individual institution, but really thinking about what the power of that network can be when we're all working together for the same common goals.